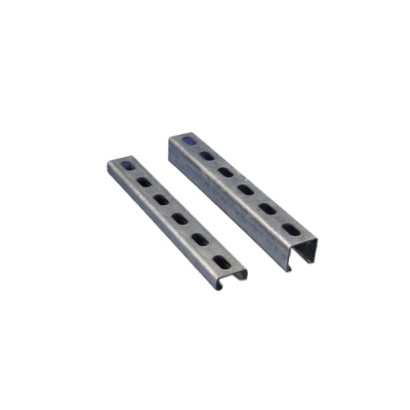

| Raw Material | Normal galvanized steel. Strip thickness : 2.0-2.5mm |

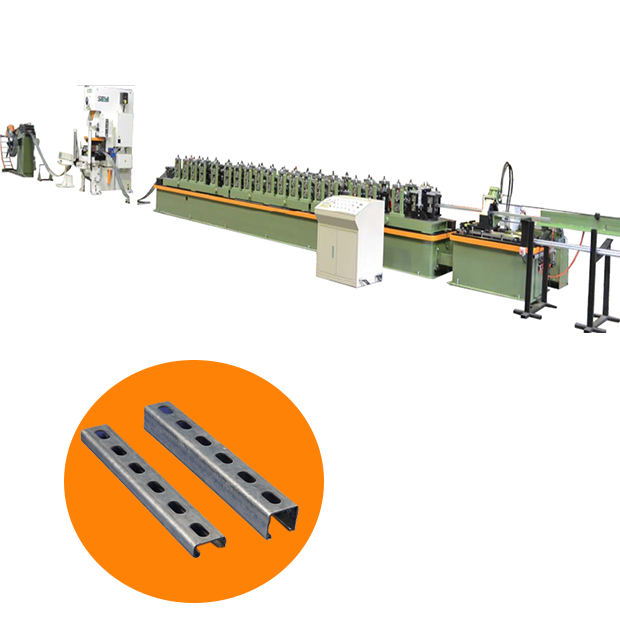

| Process | From coil →Roll forming → Automatic punching & cut-off after forming → Finished products. |

| Features | 1. Automatic roll forming process: Max. material width: 170 mm , Material thickness: 2.5 mm 2. Roller transmission by individual worm and gear reduction 3. Roll forming speed: Max. 10 meters/minute. And speed is adjustable. Roll forming speed shall be synchronized with press punching process. 4. Automatic hydraulic cut-off machine. Good design for easy operation. Cutting blade is in SKD11 material, vacuum heat treated to HRC 56゚± 1゚ 5. Product length: 1 ~ 6 Meter/pc, adjustable. Length tolerance: ± 0.2 mm |

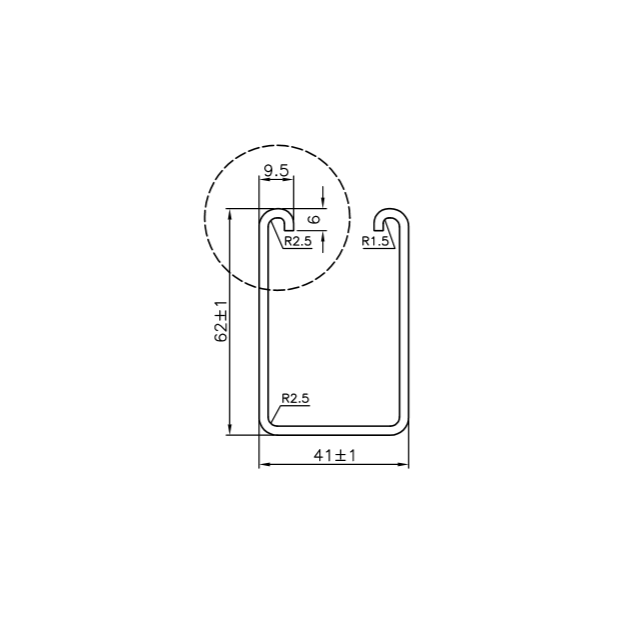

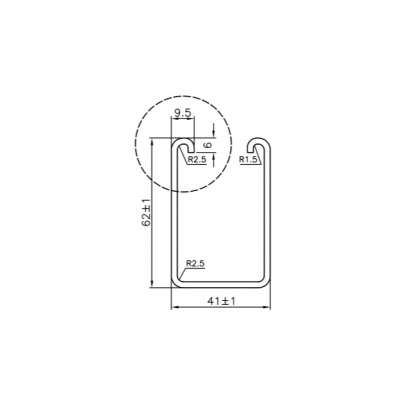

| Specification | A. Single-head type uncoiler x one unit. 1. Loading capacity: 3,000 Kgs 2. Coil specification: O.D. 1,200 mm, I.D. 480 – 510 mm, Plate width: 200 mm. 3. Coil I.D. can be adjusted by handler. 4. With a pneumatic arm to keep coil roll stretching out. 5. Driven by leveler. B. Automatic leveler with power x one unit. C. NC Feeder x one unit 1. Strip thickness: 2.5mm. 2. Max. strip width: 170mm. 3. Feeding length: 200mm per pitch. 4. Feeding activated by press. 5. Servo motor: 3HP D. Press x one unit. 1. Capacity: 80 Tons. 2. Max. speed: 50 strokes/minute. 3. Sensor controlled 4. Pressing die: 1 set for size of 41x62 5. Die insert material, the others are in SKD11. E. Cold roll forming machine with change table x one unit. 1. Model: G-400-CL type. (Chang table type) 2. Roll forming stands: 18 nos. with entry guide and idle rollers. 3. The main machine base is assembled by high-strength steel with precise welding treatment. Each stand is driven by individual worm gear reduction. All gear reduction will be driven by a common motor and shaft. 4. Main driving motor: 40 HP variable speed motor. 5. Forming rollers: one full set in material of SKD11 with vacuum heat treatment, hardness up to HRC 58-61°. 6. Roll forming speed: max. 8-10 M per minute without punching hole. And is adjustable. The roll forming line will be synchronized with the punching press and servo feeder. 7. Roll shaft: Ø 60mm, use S45C material 8. Cooling system: 1/2 HP for forming rollers x 1 set. 9. Product straightener: one set. F. Hydraulic punching & cut-off device x one unit. 1. Punching dies are in alloy steel SKD11 with vacuum heat treatment, Hardness up to HRC 58 – 61, wear-resistance, good steel structure, durable. 2. Unique design gives trouble-free operation. 3. Cut-off length: 1 ~ 6 meters, adjustable. 4. Hydraulic pack (10 HP): 1 set. 5. Hydraulic cooling system: 1 set. 6. Punching die: one set G. Product run-out table (6M) x one unit. 1. Feature: run-out table with automatic unload finished products. 2. Piling device for products piling and packing: 3 sets. H. PLC electric control system x one unit. 1. Mitsubishi PLC controller x 1 set 2. HMI control panel x 1 set. 3. Electric voltage will be confirmed before placing order. |

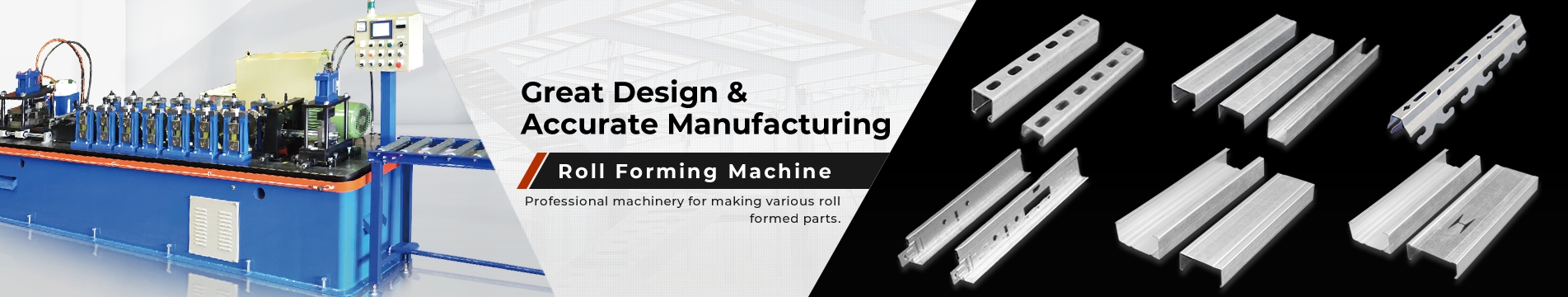

Struct Channel

Automatic Cold Roll Forming Machine For Struct (cable track)

Automatic Cold Roll Forming Machine For Struct (cable track)

Automatic Cold Roll Forming Machine. For Struct (cable track)

DETAIL