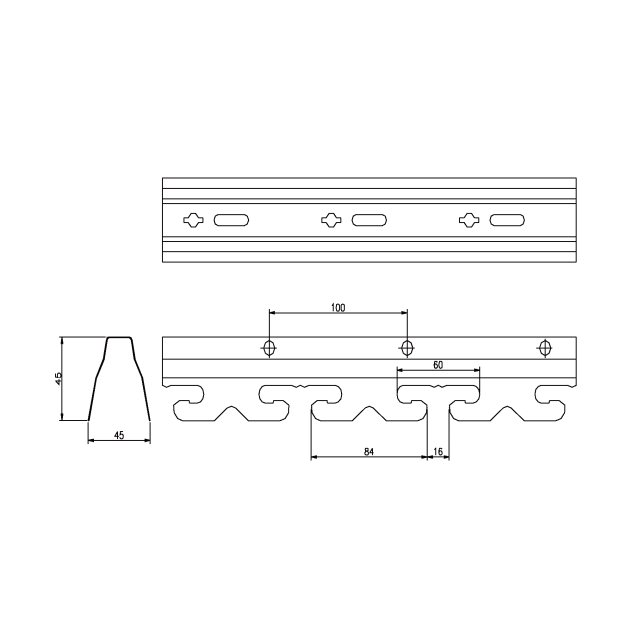

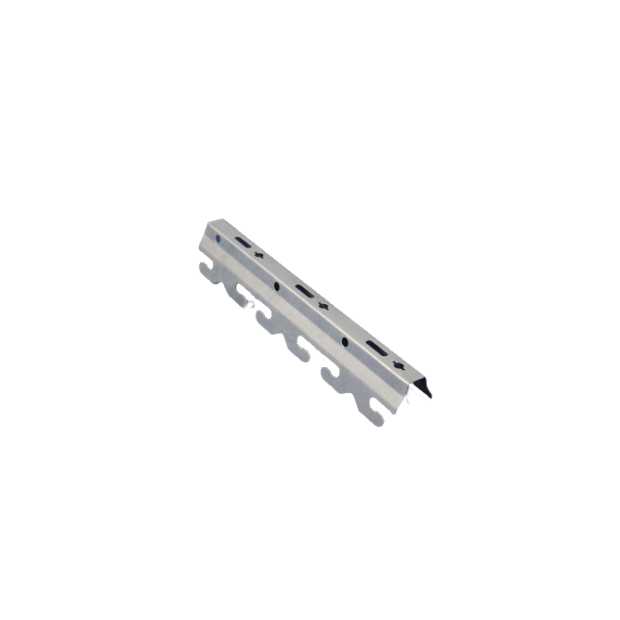

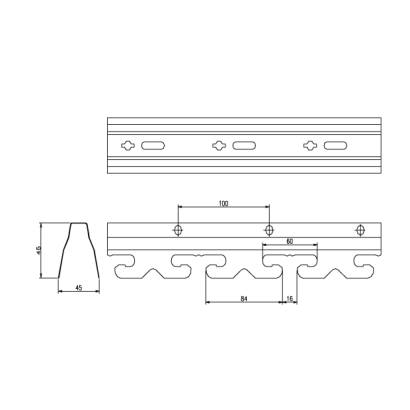

| Raw Material | Galvanized Steel, thickness: 0.6 mm |

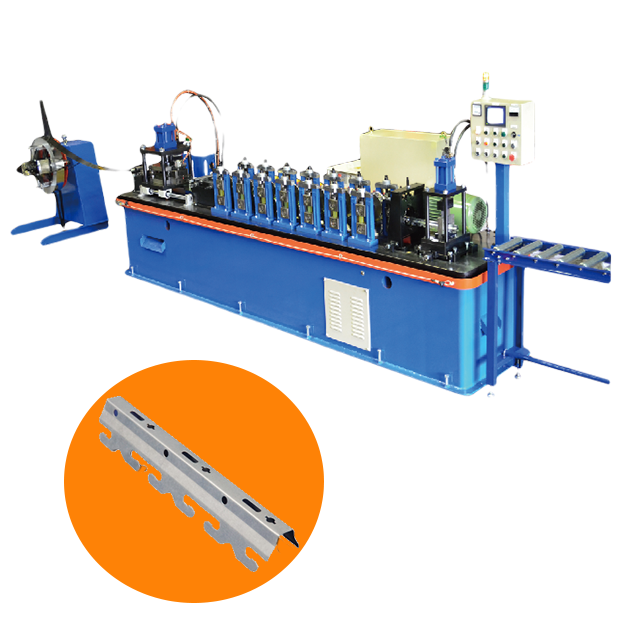

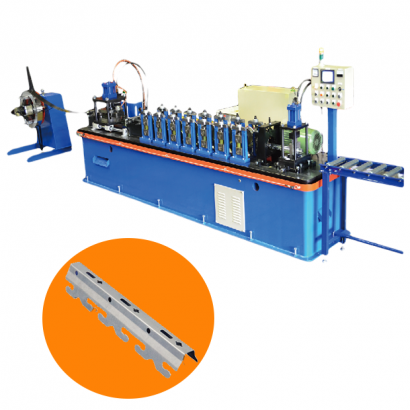

| Process | Coil→Punching→Roll forming → Cut-off to length → Finished products. |

| Features | 1. Roll forming speed: Max. 6 Meters /minute. 2. Cutting length: 1 – 6 Meters, adjustable 3. Length tolerance within ±1.0mm. |

| Specification | 1. Uncoiler x 1 Unit a. loading capacity: 1,100 kgs. b. O.D.: 1,200. Mm c. Strip width: 250 mm d. Manual tightness adjustment. 2. Hydraulic Punching device x one unit. a. Punch die x 1 set 3. Cold roll forming machine x one unit. a. Roll forming steps and stands: based on profiles and hole patterns. b. machine base: high strength steel, welding, heat treated. c. Forming rollers: one set. d. Roller shaft: Ø 40.0 mm e. Roller material: SKD11, heat treated, hardness HRc 60. 4. Hydraulic automatic cut-off device x one unit. a. Cutting die material: SKD 11, heat treated, hardness 58~61, durable design and structure. b. Cutting length: 1 ~ 6 meters, adjustable. Length tolerance with ± 0.1 mm. c. Hydraulic power pack with 5 HP motor: one set d. Cut-off die: one set e. Chiller for hydraulic power pack: one set 5. Product run-out table (6M) x one unit. Material run-out table for finished parts collection. 6. PLC electric control system x one unit. a. PLC controller x 1 set b. HMI control panel x 1 set. c. Electric voltage will be confirmed before placing order. |

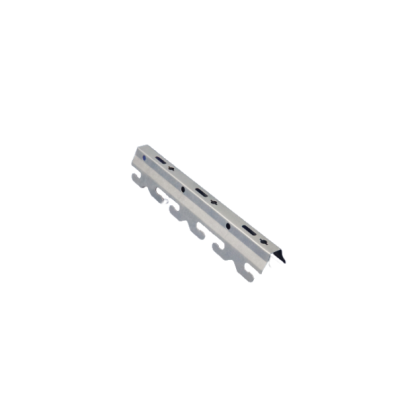

Carrier

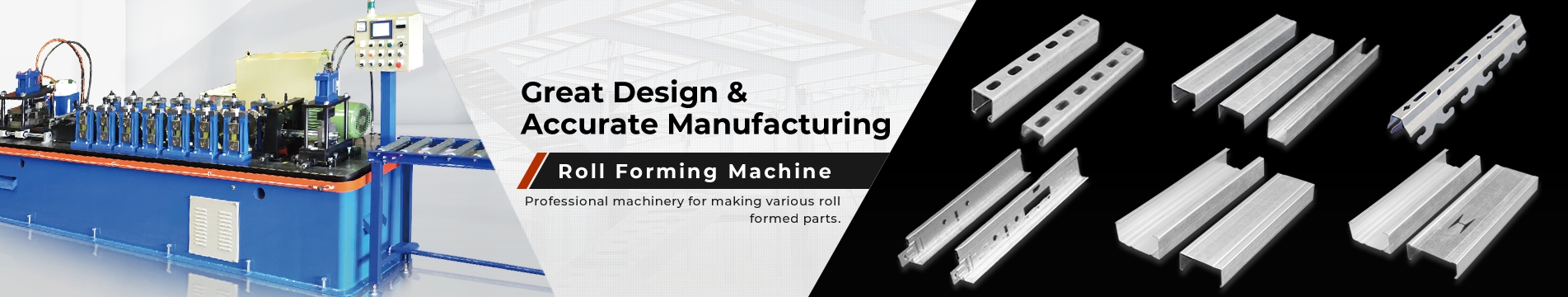

Automatic Aluminum Panel Carrier Cold Roll Forming Machine

Automatic Aluminum Panel Carrier Cold Roll Forming Machine

Cold Roll Forming Machine for Making Aluminum Panel Carrier.

DETAIL