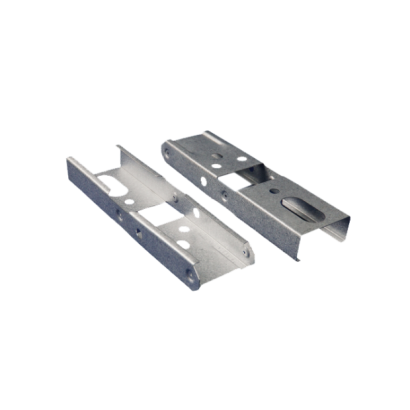

| Machining Process | Coil →Entry guide→ Punching section A (Truss, notch, lip cut, service hole) →Roll forming → Punching section B (dimple, swag) →Crimp and shear→Finished products. |

|

| RAW Material | High tensile galvanized steel G350-G550 Material thickness: 0.8-1.5mm Inspection standard: G400, 1.0mm |

|

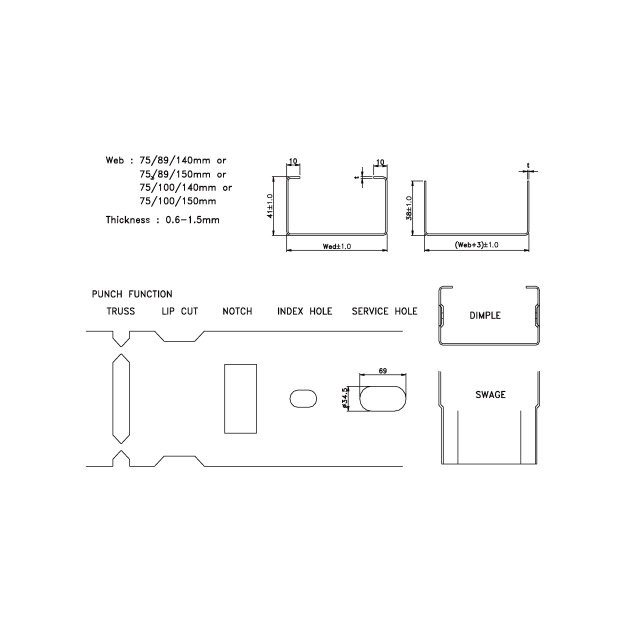

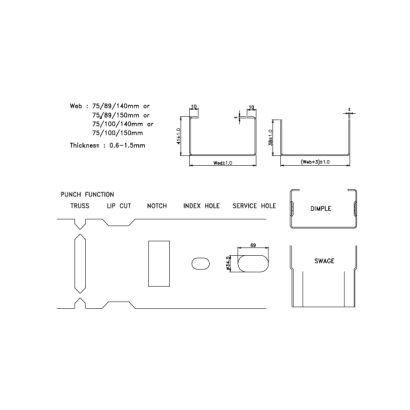

| Profile | 3 Web Size Profiles (C+C & C+U) Steel Framing System | |

| C - Profile | U - Profile | |

| A3-75/89/140 (75/89/140x41mm) or A3-75/89/150 (75/89/150x41mm) or A3-75/100/140(75/100/140x41mm) or A3-75/100/150 (75/100/150x41mm) |

A3-75/89/140 (78/92/143x38mm) or A3-75/89/150(78/92/143x38mm) or A3-75/100/140(78/103/143x38mm) or A3-75/100/150(78/92/153x38mm) |

|

| Punching Features | Service Hole, Web Notch, Lip cut, Truss, Index hole, Dimple, Swage, Crimp, Shear.jpg) |

|

| Features | 1. Fully automatic continue production, max thickness up to 1.5mm 2. Forming roller transmitting system: Driven by servo motor, individual reduction gear for each forming stand. All rollers are turning simultaneously. 3. Max roll forming speed: 30M/minute (or 1800M/hour). 4. Control system: CNC Control. 5. Forming rollers and punching dies are in alloy steel SKD11, vacuum heat treatment, Hardness up to HRC 60°, wear-resistance, and durable |

|

| Specification | A. Automatic Single Head Uncoiler x 1 Unit 1. Loading capacity: 2,200 Kgs 2. Coil specification: - O.D. 1,300 mm. - I.D. 480 – 510 mm. - Material width : 250 mm 3. Manual coil change and tighten 4. Driven by 2 HP motor B. Entry & Lubricate system x 1 Unit 1. Lubrication system: 1 set 2. Entry guide with the counter wheel: 1 set C. Punching die sets x 1 Unit 1. Punch before roll forming section, a. Truss (75/89/140), b. Notch (75/89/140), c. Lip cut (75/89/140) , d. Service hole and index hole 2. After roll forming section, a. Dimple, b. swage, c. Crimp & Shear (75/89/140) 3. Punching dies are in alloy steel SKD11, vacuum heat treatment, Hardness up to HRC 58-61°, wear-resistance,good rigid structure and durable. D. Cold roll forming section x 1 Unit 1. Forming station: 7 ~ 8 stations 2. Driving motor: 7.5KW servo motor 3. Forming rollers: one full set for 75/89/140 mm, 3 sizes. 4. Roller shaft: φ50mm, mild steel, heat treated and grinding. 5. Rollers: Alloy steel SKD11, vacuum heat treatment, hardness up to HRC 58 ~ 61°, wear-resistance, rigid structure and durable. 6. Hitachi industrial printer: 1 set E. Hydraulic system x 1 Unit 1. Hydraulic motor: 7.5HP with 3.0Liter accumulator. 2. Fan type oil cooling system: 1set F. Run out table (4.5M) x 1 Unit G. Computer control system x 1 Unit 1. CNC controller: 1 set 2. IPC with Win 7 PRO and control software x 1 set 3. 17” touch screen x 1set 4. Input power: will arrange according client power source. 5. Controller power: DC24V/Ac220V H. Vertex BD Pro Design software x 1 license copy 1. The Design software can make C+C & C+U design. 2. The Design software with 2D and 3D function. 3. The CAD can be transmitted into CAM file for manufacturing. |

|

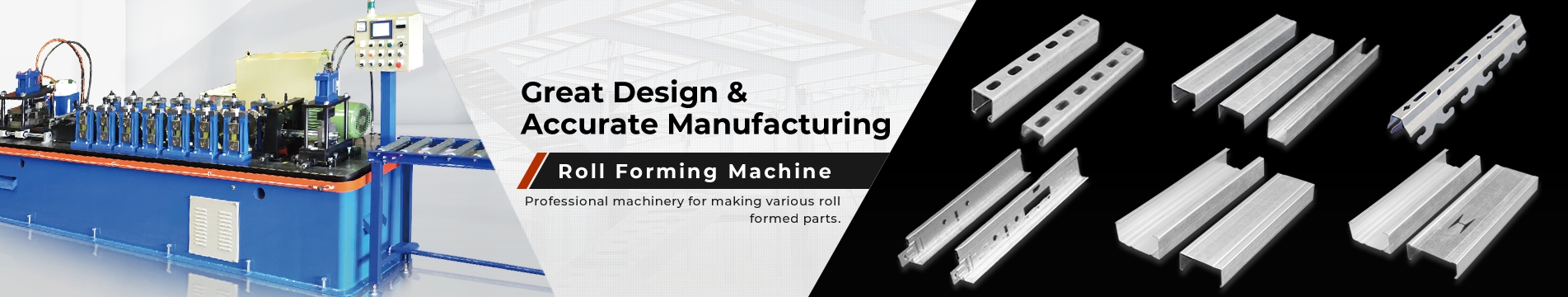

Roll Former A3

Automatic Light Gauge Steel Frame Cold Roll Forming Machine in 3 Sizes

Automatic Light Gauge Steel Frame Cold Roll Forming Machine in 3 Sizes

Cold Roll Forming Machine for making 75/89/140 sizes steel frame and studs.

DETAIL